How the RoboDose uses Phidgets to Safely Deliver Medication

by Kahht

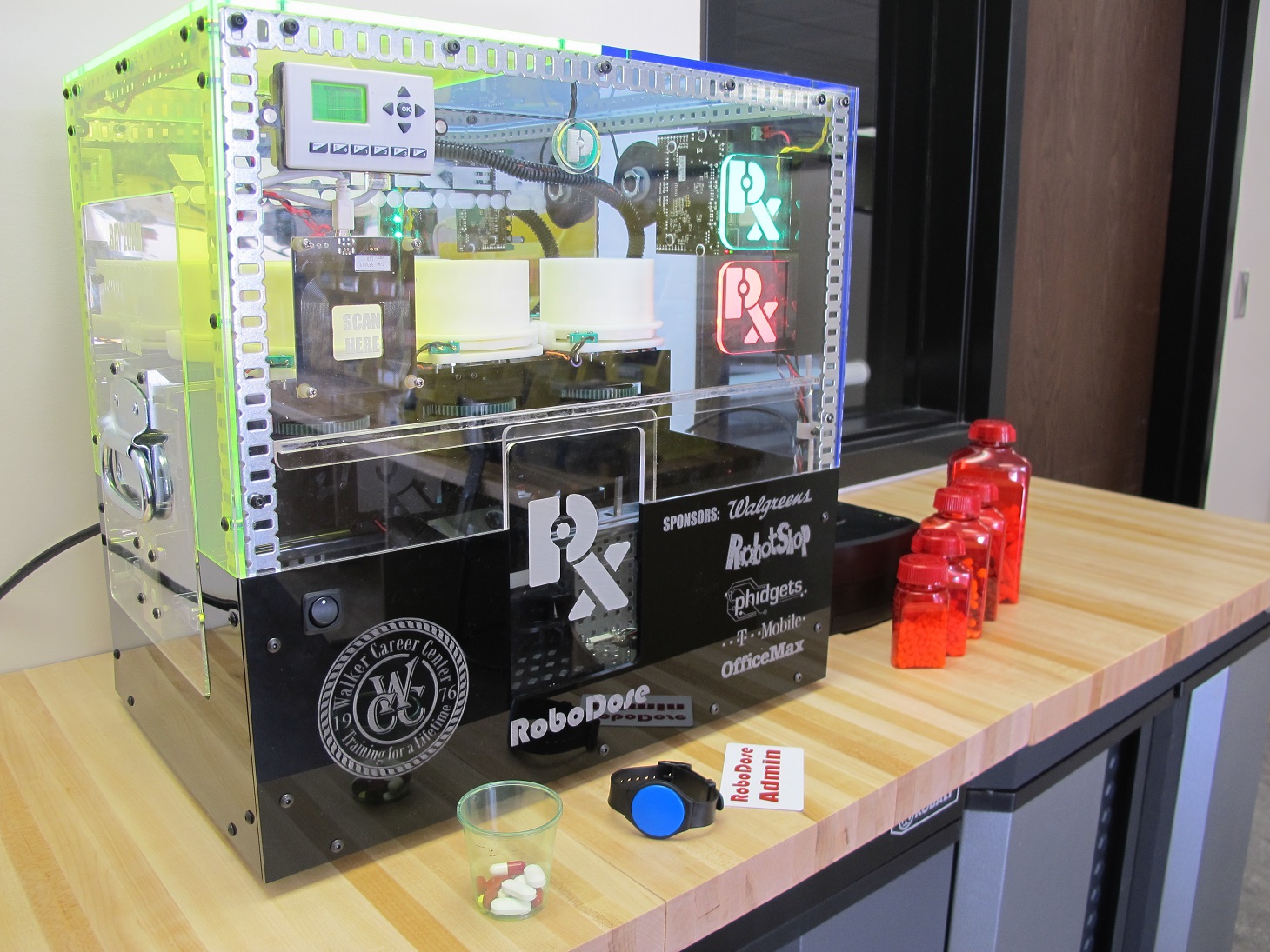

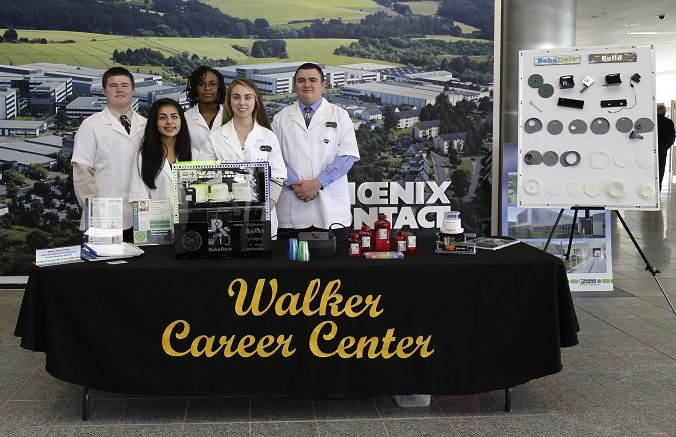

Earlier this year, a group of high school students from Walker Career Center in Indianapolis competed in Phoenix Contact's Nanoline contest. They call themselves the Nano Consultants, and their vision was to build a device that would dispense proper dosages of medications to patients prone to forgetting their medication. They call it the RoboDose. They succeeded in not only making the machine, but also securing first place in the Nanoline contest hosted every year by Phoenix Contact.

The Nanoline contest challenges students to design and build a working automation system using the Nanoline controller and nanoNavigator software. Other winning teams have made underwater drones, mobile solar charging stations and real-life WALL-E robots, but the RoboDose team is the first to use Phidgets in their winning design.

I caught up with the Nano Consultants to talk about their project.

What inspired you to work on this project?

Nano Consultants: Phoenix Contact left the base goals for this contest extremely open-ended. This allowed us to take their equipment in just about any direction we wanted. Through numerous brainstorming sessions we arrived at a solution that would solve a real world problem. With all of us having grandparents or older relatives in our lives that take medication, this was a problem that hit home for all of us. We were inspired to get a chance to not only help elder family members with a safer way to take medicine, but also create a machine that would provide all families with peace of mind.

We entered this contest wanting an opportunity to use the skills and knowledge that we have been working on for the past several years in our high school engineering courses. We were able to also take the opportunity to step out of our comfort zone in several areas as we added several new skills to our portfolio.

How did you use Phidgets?

NC: Phidgets material used:

- Phidgets SBC (Single Board Computer)

- Receive data from the RFID Moduleii. Transferred data to the PLC Industrial Controller

- RFID Read-Write Module

- Allowed limited access to the machine for both administrators and patients

- Open the pill load access

- Open the main door for timed dosages to a specific user

- Allowed access to the higher level machine settings and configuration

- Allowed limited access to the machine for both administrators and patients

- RFID Watch Straps

- Allowed each patient to have individualized access to a specific machine

- RFID Credit Card Tag

- Added total administrator access to all machines in a network of devices

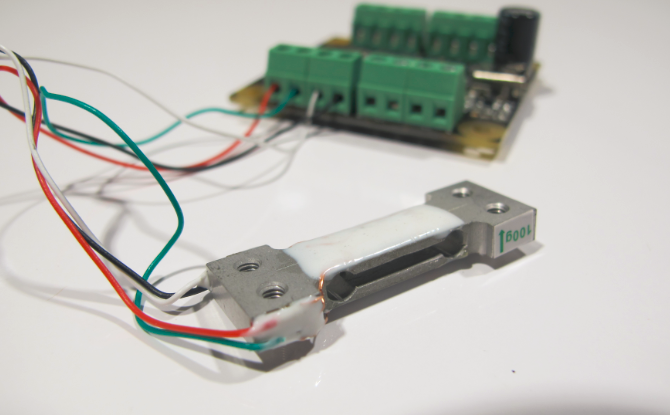

- Micro Load Cell (Stress Strain)

- Weighed each individualized dosage to ensure dosage accuracy

- Multiple Roller Micro Switches

- Use to help the indexing of each pill bay in our feeder system that we designed

- Roll Ball Switch

- Used for proximity – Provide feedback for when the main access door had completely opened

- Magnetic Contact Switch

- Used for proximity – Provide feedback for when the main access door had completely closed

Why did you choose Phidgets?

NC: We needed a company to provide safe usage of our machine through analog and digital sensors. Phidgets offered the RFID technology that we wanted to integrate into our project and jumped at the chance to help and sponsor us to bring our idea to life.

What obstacles did you have? How did you overcome them?

NC: Java was an entirely new language to us and we discovered that we had a lot of learning to do to get the equipment to work the way we wanted. In the end we were making everything much harder than it need to be once we were able to establish communication with the SBC and get the program loaded onto it. We wanted to use the RFID Read-Write Module and the SBC to provide additional identification safety to our machine, but we had issues with downloading our program to the SBC. As well, we went through a lot of trouble shooting trying to get the Micro Load Cell to integrate with our industrial controls bridge. We had to be extremely careful with it because of the very small fragile wires and had to be able to work with the different readings the MLC gave us for different pills. We overcame both of these by learning how to connect to the SBC through Phidgets technical support and creating an “average” value for the MLC to read to determine if our pill count was correct in dosage.

What skills were necessary for you to finish the Robodose? What did you have to learn?

NC: Teamwork and dedication were two important values in the creation of RoboDose. We had to not only spend many hours together to finish our machine, but we had to be able to act as a team to present our product in front of judges to our best capabilities. We not only learned how to use many different tools available to us in our career center, but work together to connect all of our individual skills with a wide variety of community and industrial partners to create an award-winning project.

What was you favourite part of the process?

NC: Our favorite part was to finally be able to be able to represent the United States and present our project to thousands of people in a world renowned tech fair. The interest we received in our machine was worth all of the hours we spent in the design and creation.

Every one of our members was a part of the Project Lead the Way Pre-Engineering program. Through trial and error, we all received the chance to experience the real world application of what we learned in class. Each person spent over 250 + hours on our project, spending our entire winter break and subsequent week-long school cancellation working on the project except only Christmas and New Year's Eve.